ETIRA CALLS FOR INCREASED RoHS CHECKS ON IMPORTED TONER & INKJET CARTRIDGES

March 26, 2019

Independent tests were undertaken by the German test lab LGA show that imported new non-OEM toner cartridges containing high levels of decaBDE breach RoHS safety limits

Independent tests were undertaken by the German test lab LGA show that imported new non-OEM toner cartridges containing high levels of decaBDE breach RoHS safety limits

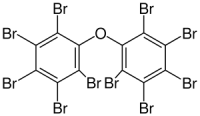

Brussels, 27 September 2018: – An article published in German industry magazine Digital Imaging this week reveals high levels of Decabromidiphenylether (decaBDE) in imported newbuilt non-OEM toner cartridges from two well-known brands. The story is based on tests done by the independent German test lab LGA. DecaBDE is a flame retardant found in IT and telecommunications equipment, such as printers and copying equipment. Flame retardants have been widely used in plastics of electrical appliances to mitigate fire and explosion risks. In February 2017 the European Commission added decaBDE to the REACH Annex XVII list of restricted substances, because emissions and widespread distribution of decaBDE in the environment creates a high potential for long-term (health) exposure for humans.

ETIRA, the European Toner and Inkjet Remanufacturing association is calling for the EU and member states to actively ensure that all cartridges imported into the European Union comply in every manner with European WEEE, REACH and RoHS directives and intellectual property regulations to protect the health and well-being of EU citizens and the environment.

ETIRA is also calling for the EU to mandate that all toner and inkjet cartridges placed on the market are designed and manufactured so that they are suitable for reuse as a cartridge. ETIRA again stresses that for consumers and businesses, the best option is a remanufactured OEM cartridge, as supplied by the 3,000 companies across Europe. Remanufactured OEM cartridges are less expensive than new OEM cartridges but are 100% environment-friendly.

Europe consumes over 130 million toner cartridges a year, while the total toner and inkjet market is worth €17 billion. More than 5 million toner cartridges are new non-OEM cartridges, and they may not be suitable for reuse and may require specialised handling and material recovery. Eliminating toxic products from the market and ensuring cartridges are reused more often could generate more than 16,000 new SME jobs across the European Union.

Tags

CartridgesDecaBDE

Imports

Printers

RoHS

February 2018: EU-commissioned study on cartridge market clearly concludes: more regulatory action is needed to promote cartridge reuse

The EU’s “Study on the implementation of product design requirements set out in Article 4 of the WEEE Directive – The case of re-usability of printer cartridges” came out in late February 2018. It found that the cartridge market is very competitive, but the regulatory environment is not well suited to promoting reuse of products or encouraging dematerialisation and greater material efficiency. Significant alterations are proposed. The study writers promote using the Extended Producer Responsibility (EPR) as key to enhancing overall cartridge re-use.

The EU’s “Study on the implementation of product design requirements set out in Article 4 of the WEEE Directive – The case of re-usability of printer cartridges” came out in late February 2018. It found that the cartridge market is very competitive, but the regulatory environment is not well suited to promoting reuse of products or encouraging dematerialisation and greater material efficiency. Significant alterations are proposed. The study writers promote using the Extended Producer Responsibility (EPR) as key to enhancing overall cartridge re-use.

Re. market data, they say that clones represent 5% of toner and inkjet markets respectively (which seems a serious underestimate). On the OEM’s Voluntary Agreement Imaging Equipment, the study says that its data shows the VA does not promote cartridge reuse. The study suggests to revise the VA, and include parameters on lower emissions of printing. The car industry has examples of such mandatory CO2 reduction targets. Reducing cartridge complexity (clever chips !) can be one of the ways to do that. On the Ecolabel, the study supports developing an EU Ecolabel criteria for remanufactured cartridges (as requested by ETIRA).

The study identified concerns and corresponding actions as follows:

- Creating a level playing field for the new and re-use/second-hand markets.

- Consolidating patent holder and OEM protection and second user rights

- Improving design for reuse, recycling and recovery

- Ensuring reused cartridge performance.

- Improving re-use performance disclosure.

To improve the market situation for both legitimate new and reused cartridges, a range of measures is proposed for consideration:

- Addressing the issue of ‘rogue clone’ imports

- Ensuring reuse agents do not misrepresent reused units as OEM products.

- Improving access to cartridge design and consumables specifications

- Revising the EU GPP criteria to address ‘remanufactured and refilled cartridges.

- Improving user information on all cartridge packaging to reveal true performance.

- Creating a rating system for cartridge quality (‘failure rate’) matched to user expectations.

- Rationalising acceptable phrases to be used to describe new and reused cartridges.

- Reviewing the Voluntary Agreement so that data on rates of take-back, re-use, recycling and other recovery operations is routinely collected and published.

- Expanding the scope of actions by producers of cartridges to promote and support the reuse option as an alternative to take-back.

In 2016/2017, ETIRA had provided substantial input to the writers of the study. We are glad to see that it now identifies current OEM market behaviour as not contributing to the promotion of cartridge reuse, and takes on board several of our recommendations to address this problem. We will now reach out to regulators to put this into action!

Tags

CartridgesEU

EU Comission

Legislation

REgulation

ETIRA-commissioned tests find hazardous decaBDE in more newbuilt non-OEM cartridges

December 17, 2018

Tests find more newbuilt non-OEM cartridges containing hazardous decaBDE chemical that is not allowed in electronic products above certain levels.

In late October, industry media reported (The Recycler and Digital Imaging) that several newbuilt non-OEM cartridges had been found to contain excessive levels of Decabromodiphenylether (DecaBDE), a halogenated flame retardant that, because of its health risks, has been prohibited in the EU since 2008 in electronics above certain levels, and fully prohibited in many other products. The original HP equivalent did not contain DEcaBDE.

ETIRA, the European association of companies that remanufacture OEM-printer cartridges for reuse, recently purchased several newbuild non-OEM cartridges and commissioned tests from the German lab TüV Rheinland/LGA to see if there is a pattern.

The results showed that four cartridges had DecaBDE levels ranging from 2,000 mg/kg to a staggering 17,000 mg/kg, although only 1,000 mg/kg is allowed under the EU’s RoHS directive (Restriction on Hazardous Substances) 2011/65/EU. These four products Included Bubprint, sold on Amazon by Druckerpatronen Express, DE, and Prestige Print sold on Amazon by J&H GREENTECH and Trading Ltd, UK, (both compatible to HP17A), as well as Koala sold on Amazon by Lucky Suppliers Handels GmbH, DE and Yellow Yeti, sold on Amazon by Simple Printing Ltd, UK (both compatible to HP26X).

“These results are very worrying”, said Vincent van Dijk, ETIRA Secretary-General. “The tests showed that these were not isolated accidents, but that there is a major systemic issue in the overall market with newbuilt non-OEM cartridges from Asia that contain extremely high levels of a hazardous chemical. It is very serious that thousands of newbuild non-OEM cartridges are sold across Europe every day if many of them violate EU health and safety regulations. And a lot of suppliers even claim that they are REACH and/or RoHS compliant, which they obviously are not. ETIRA again calls on EU and national authorities to remove all hazardous cartridges from the market, and customers should refrain from buying them. “

ETIRA will further ascertain the REACH/RoHS registrations and factories of origin of these products, as well as test more products. We are also reporting many cartridge suppliers to national authorities for failure to register under WEEE.